Mini Differential Swerve Drive

Mini Differential Swerve Drive is a project I started over a year ago. In FIRST Robotics Competition, Swerve Drive is a high-risk high reward drivetrain type that combines the omnidirectional capabilities of mechanism drive with the stellar traction of normal tank drive. The downside is the mechanical and programming complexity that is required to pull it off. For most teams, it is simply not effort effective to use, but in recent years it has been becoming more popular. For example teams like 2767 Stryke Force, 2910 Jack in the Bot, and 1323 MadTown have all brought swerve to Einstein finals.

Yes, swerve drive is very cool, but I am not a fan of the bulky, heavy, and complicated modules. I would normally have never touched swerve drive but a post on Chief Delphi caught my eye about a year and a half ago.

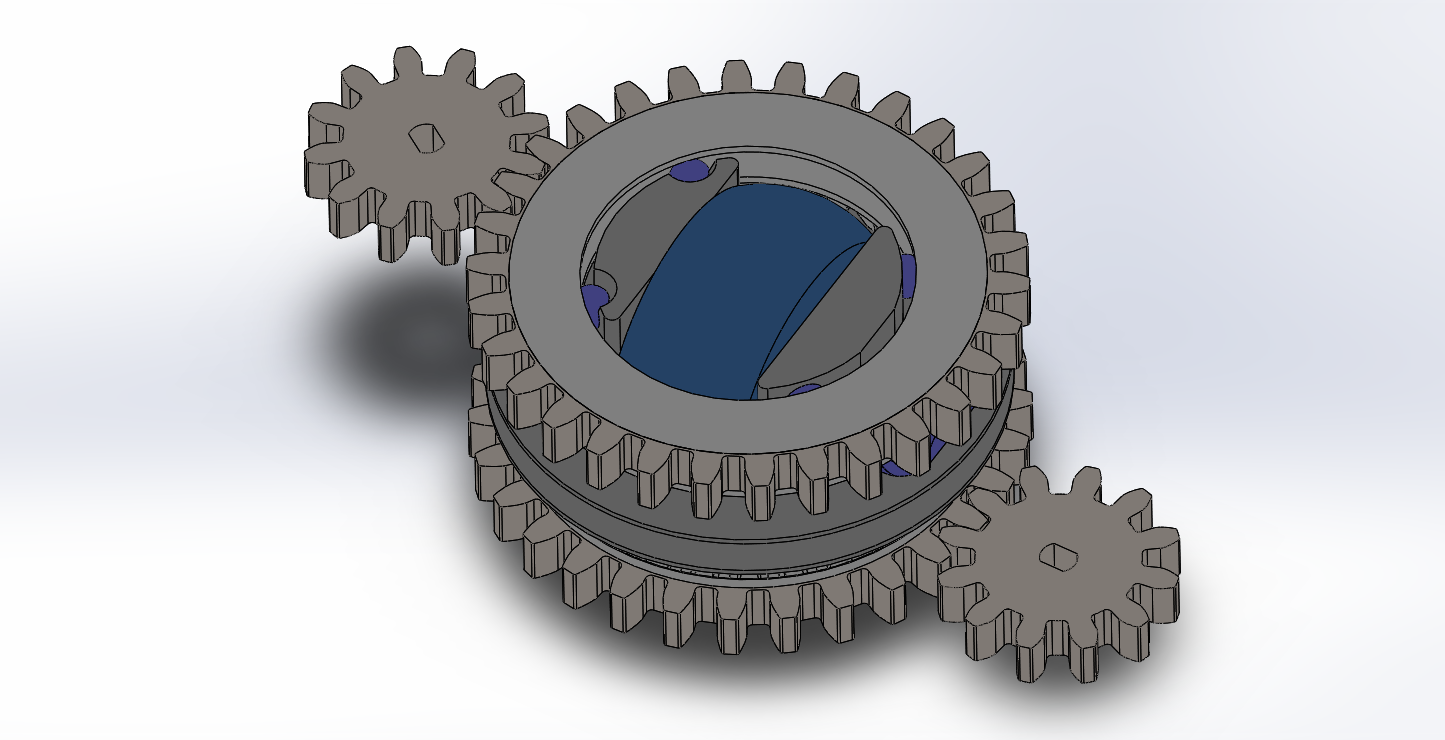

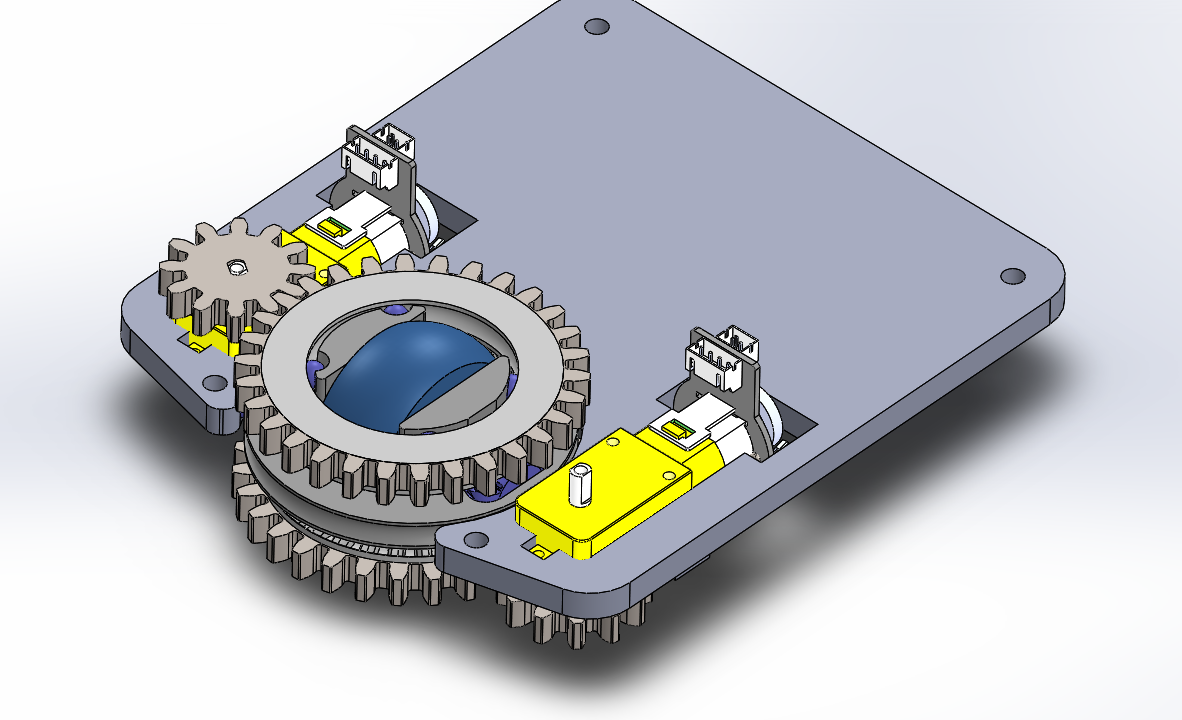

At the time and to this day I am stunned with how clean and elegant this 971 module is. I was inspired to copy create my own version of the design and use it in MiniFRC 5. A friend and I worked on it a lot during our winter break in late 2017, even to the point where we got a module working (Sorry for the poor video quality).

We didn’t end up using it in MiniFRC 5 because the modules are quite large, it would have been too much to try to fit even 3 modules within the frame limit, let alone other robot mechanisms. I plan to one day build a 3 module drivetrain. But until then I will go ahead and post the CAD here.

We didn’t end up using it in MiniFRC 5 because the modules are quite large, it would have been too much to try to fit even 3 modules within the frame limit, let alone other robot mechanisms. I plan to one day build a 3 module drivetrain. But until then I will go ahead and post the CAD here.

https://drive.google.com/open?id=1odAfKXtke28jzhcQ9p3HLBChvFibkNH_

It’s mostly 3d printed, and you may have to adjust the horizontal expansion setting on your printer as the tolerances are very tight. The only metal parts are 1/4in ball bearings, 5/8in OD bearings, and (most annoyingly) a 3/16 hex rod for the main axle. If I were to bring this project back I would honestly use plastic Lego axles instead. The modules are built to run off of these TT motors but you could modify the small spur gears for any shaft. Whatever you use just make sure they have encoders or you’re gonna have a bad time. I cut a corner when designing the big ring gears. they are actually two gears (a bevel gear and a spur gear) that need to be combined before they are exported as an STL for printing.